In any printing operation, from small-scale custom shops to large industrial facilities, the printhead is the heart of the machine. Its delicate nozzles are responsible for precisely depositing ink to create vibrant, sharp images. When they perform flawlessly, business runs smoothly. But when they clog, operations grind to a halt, and the costs start to mount—not just in wasted ink and materials, but in lost time and expensive repairs.

What if you could prevent the single most common point of failure in your printers? This is where a dedicated maintenance tool like the Printhead Doctor becomes essential. This post explores the significant advantages of integrating a professional printhead recovery system into your workflow, highlighting how it can save your business thousands in early replacement costs and operational downtime.

Understanding the Enemy: What Causes Printhead Clogs?

Before diving into the solution, it's important to understand the problem. Printhead clogs are a persistent issue in the printing industry. They can be caused by several factors:

- Dried Ink: When a printer sits idle, even for a short period, the ink within the microscopic nozzles can dry and harden, creating a blockage.

- Air Bubbles: Air can get trapped in the ink lines, disrupting the flow and causing nozzles to fire incorrectly or not at all.

- Debris and Dust: Environmental contaminants can find their way into the ink system or onto the printhead's surface, leading to blockages.

- Ink Incompatibility: Mixing different types of ink or using poor-quality ink can cause chemical reactions that result in pigmented sludge, which is a primary cause of stubborn clogs.

A single clogged nozzle can lead to banding, color inaccuracies, and blurry prints. A severely clogged head often means one thing: a costly replacement.

The Printhead Doctor: More Than Just a Cleaning Cycle

Most modern printers come with a built-in cleaning cycle. While useful for minor issues, these automated functions are often insufficient for tackling serious blockages. They primarily work by flushing a large amount of ink through the nozzles, which not only wastes expensive ink but can also fail to dislodge hardened deposits.

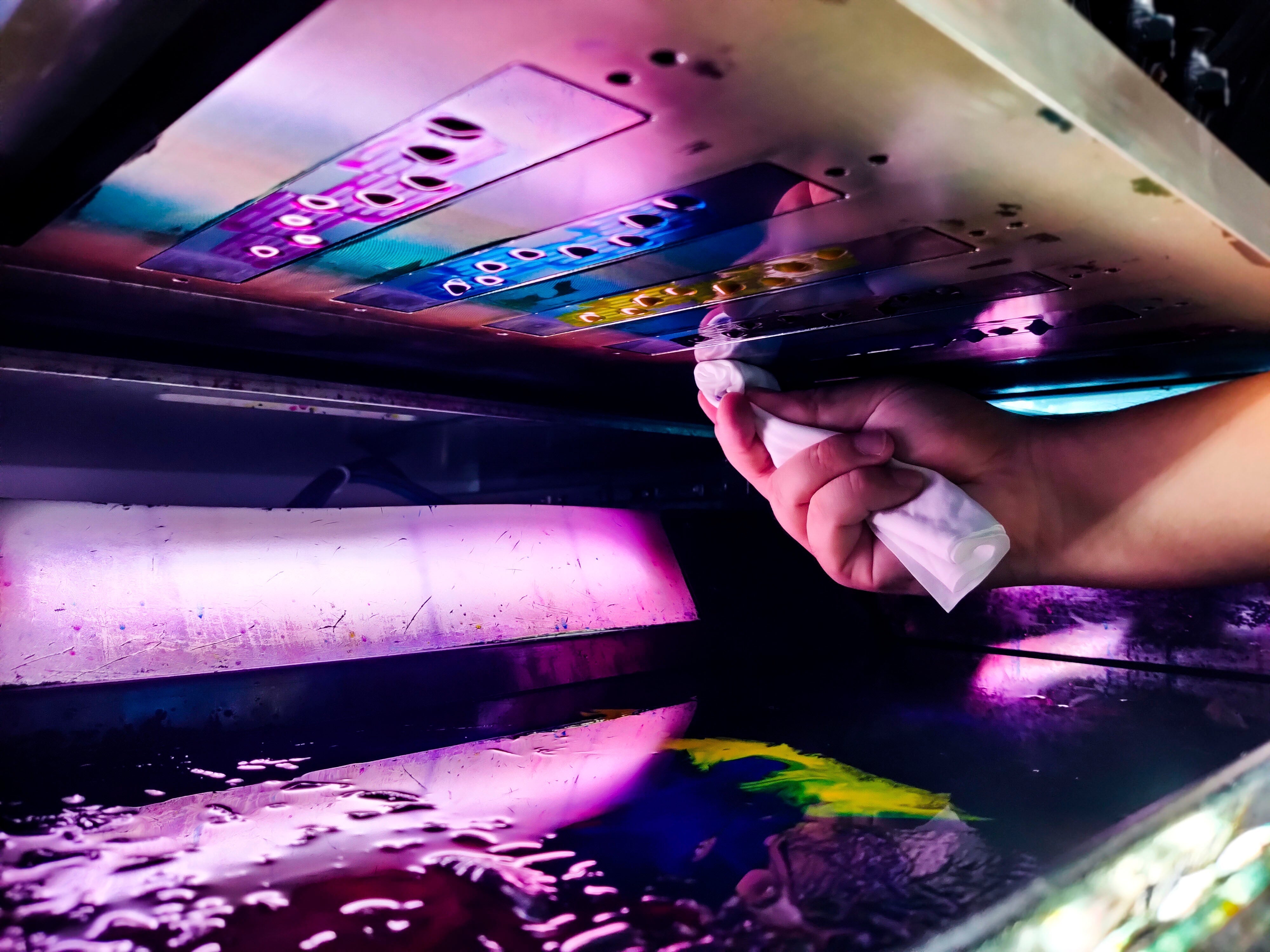

The Printhead Doctor offers a more advanced, targeted approach. It’s an external system designed specifically for deep cleaning and recovering printheads. By combining controlled pressure, gentle heat, and specialized cleaning fluids, it can dissolve stubborn clogs that internal cleaning cycles can't touch.

How It Works: A Proactive Approach to Maintenance

Instead of just pushing more ink through, the Printhead Doctor uses a combination of methods to restore flow. It can create a vacuum to gently pull blockages out or apply controlled positive pressure to push dissolved particles through. This process is far more effective and less wasteful than a standard printer clean.

By incorporating this tool into a regular maintenance schedule, you shift from a reactive "fix-it-when-it-breaks" model to a proactive one. This preventative care is the key to unlocking massive savings and operational efficiency.

The Financial Impact: Saving Thousands on Replacements

The most direct and significant advantage of using the Printhead Doctor is the massive reduction in replacement costs. A single commercial-grade printhead can cost anywhere from a few hundred to several thousand dollars. For businesses running multiple printers, this expense can quickly become a significant financial burden.

Scenario: A Wide-Format Printing Business

Imagine a sign and graphics shop running three wide-format printers. Each printhead costs approximately $1,500 to replace. Without a proper maintenance system, the shop might find itself replacing one printhead per machine each year due to severe clogging.

- Annual Replacement Cost: 3 heads x $1,500/head = $4,500

Now, consider the same shop using the Printhead Doctor for regular maintenance. By keeping the printheads in optimal condition, they can easily double or even triple their lifespan. Instead of replacing them annually, they might only need to do so every two to three years.

- Savings Over Two Years: $4,500 (avoids one full replacement cycle)

- Savings Over Three Years: $9,000 (avoids two full replacement cycles)

These are conservative estimates. For larger operations with dozens of printers, the savings can easily run into the tens of thousands of dollars annually. The initial investment in a Printhead Doctor system is often recouped after saving just one or two printheads from premature failure.

Beyond Replacements: The Hidden Savings of Reduced Downtime

The cost of a failed printhead isn't just the price of the part itself. Every minute a printer is offline is a minute you aren't producing sellable goods. Downtime introduces a cascade of other costs:

- Lost Revenue: Inability to complete customer orders on time can lead to lost sales and damaged client relationships.

- Wasted Labor: Employees may be left idle while waiting for a technician or for a new part to arrive. Their wages become a sunk cost during this period.

- Material Waste: Failed print jobs due to clogging result in wasted ink and media, from expensive vinyl to specialty papers.

- Rush Shipping Fees: When a printhead fails unexpectedly, you often have to pay for expedited shipping to get a replacement part quickly, adding another layer of expense.

By preventing the clogs that cause printer failure, the Printhead Doctor ensures consistent uptime. This reliability allows you to meet deadlines, maintain a smooth production schedule, and maximize the productivity of your team and equipment.

Extending Lifespan and Ensuring Quality

Consistent, high-quality output is non-negotiable. A well-maintained printhead delivers the flawless performance your customers expect. Regular cleaning with the Printhead Doctor prevents the gradual decline in quality that often precedes a total head failure. Minor banding or nozzle drop-out can compromise a print, forcing a costly reprint.

By keeping every nozzle clear, you ensure:

- Vibrant and Accurate Colors: No missing jets to disrupt color profiles.

- Sharp, Crisp Details: Perfect nozzle firing for fine lines and text.

- Consistent Output: Every print in a run looks as good as the first.

This level of quality control protects your brand's reputation and reduces the waste associated with subpar prints.

Is the Printhead Doctor Right for Your Operation?

Investing in a professional printhead maintenance system is a strategic decision that pays for itself. Whether you run a small custom apparel business with a single DTG printer or a massive industrial printing facility, the core benefits remain the same: reliability, quality, and significant cost savings.

Stop thinking of printheads as disposable components. With the proper care, they are long-term assets. By making the Printhead Doctor & Recovery Solutions a part of your standard operating procedure, you can protect your investment, slash your operational costs, and keep your business printing smoothly for years to come.