Beschreibung

- Dropmaster 2 (Automatic Bi-Directional Alignments)

- Feed Master (Automatic Feed Roller Adjustment)

- i-screen Print Effects- Multiple Waveforms that Mitigate Banding

- Media Tracker (Roll Remainder Tracking)

- White Ink Circulation

- Auto Cleaning and Maintenance

- Washability Test AATCC61-2A [AATCC 61 Method 2A]

XPD-924D Speeds

| Printer Mode | Resolution | Pass | Printing Speed [ft2/h] | Printing Speed [lm/h] | Printing Speed [lft/h] | Time for 328 lft Roll [h] |

|---|---|---|---|---|---|---|

| High Speed | 900×600 | 3 | 17.5 | 188 | 29.0 | 3.5 |

| Production | 600×1200 | 4 | 13.5 | 145.0 | 22.0 | 4.5 |

| Quality | 900×1200 | 6 | 9.0 | 96.0 | 15.0 | 6.7 |

| High Quality | 1200×1200 | 8 | 6.7 | 72.0 | 11.0 | 9.0 |

Characteristics

- High-Speed Production – Maximize efficiency with rapid print output.

- Cost-Effective Ownership & Operation – Minimize costs while maximizing performance.

- Durable Transfers – Achieve longevity comparable to screen printing.

- Exceptional Flexibility – Prints stretch and recover seamlessly.

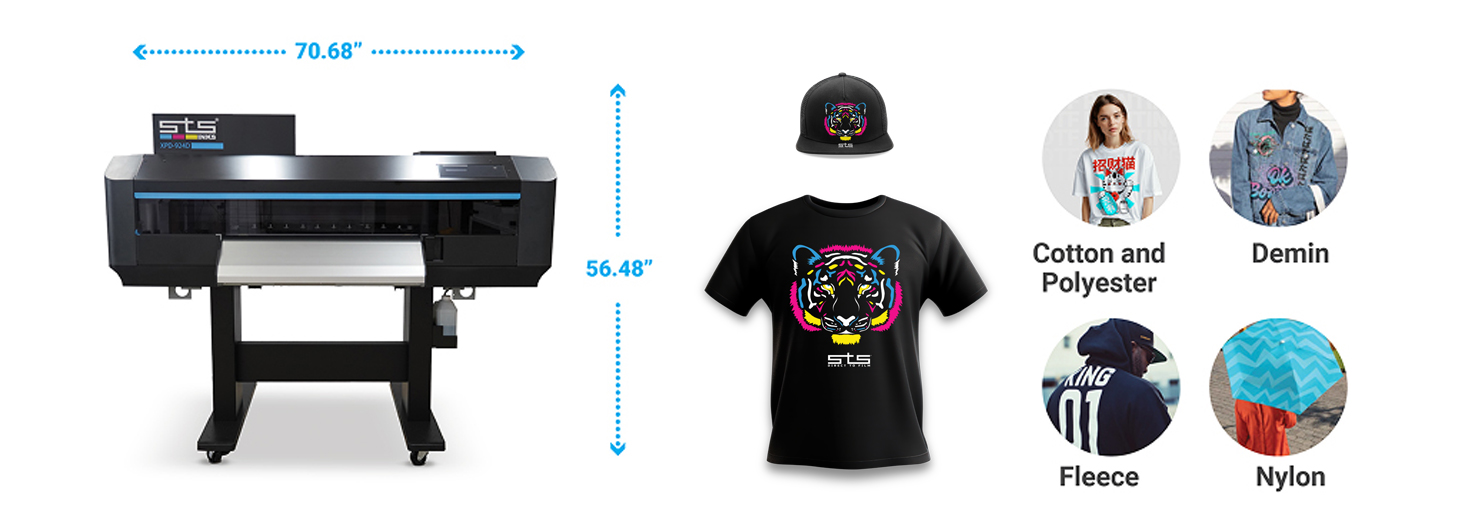

- Versatile Application – Adheres to any fabric with ease.

- Fast Heat Press Time – Apply transfers in under 15 seconds.

Features

- High-precision Heavy-duty Aluminum Rail System for High Quality and Stable Printing.

- Ease-of-use Side Mounted LAN and Power Plugs and LED Operation Panel.

- New AccuFine HD Printheads Provide Faster Speeds with Exceptional Quality.

- Built-in Sensors for Operator-Driven Automatic Bi-directional and Page feed Alignments.

- Improved Front Dryer System for 20% Faster Ink Dry Times.

- Internal LED Lighting for Unobstructed Print.

- Updated Media Angles and Media Feeding Mechanism to Allow for Easy Loading and Page Feed for DTF Film.

- Viewing and Maintenance Access.

- Includes the Mutoh Status Monitor (MSM) Companion Software for Convenience and Efficiency: Records Print History, Job Cost Analysis, Remote Access.

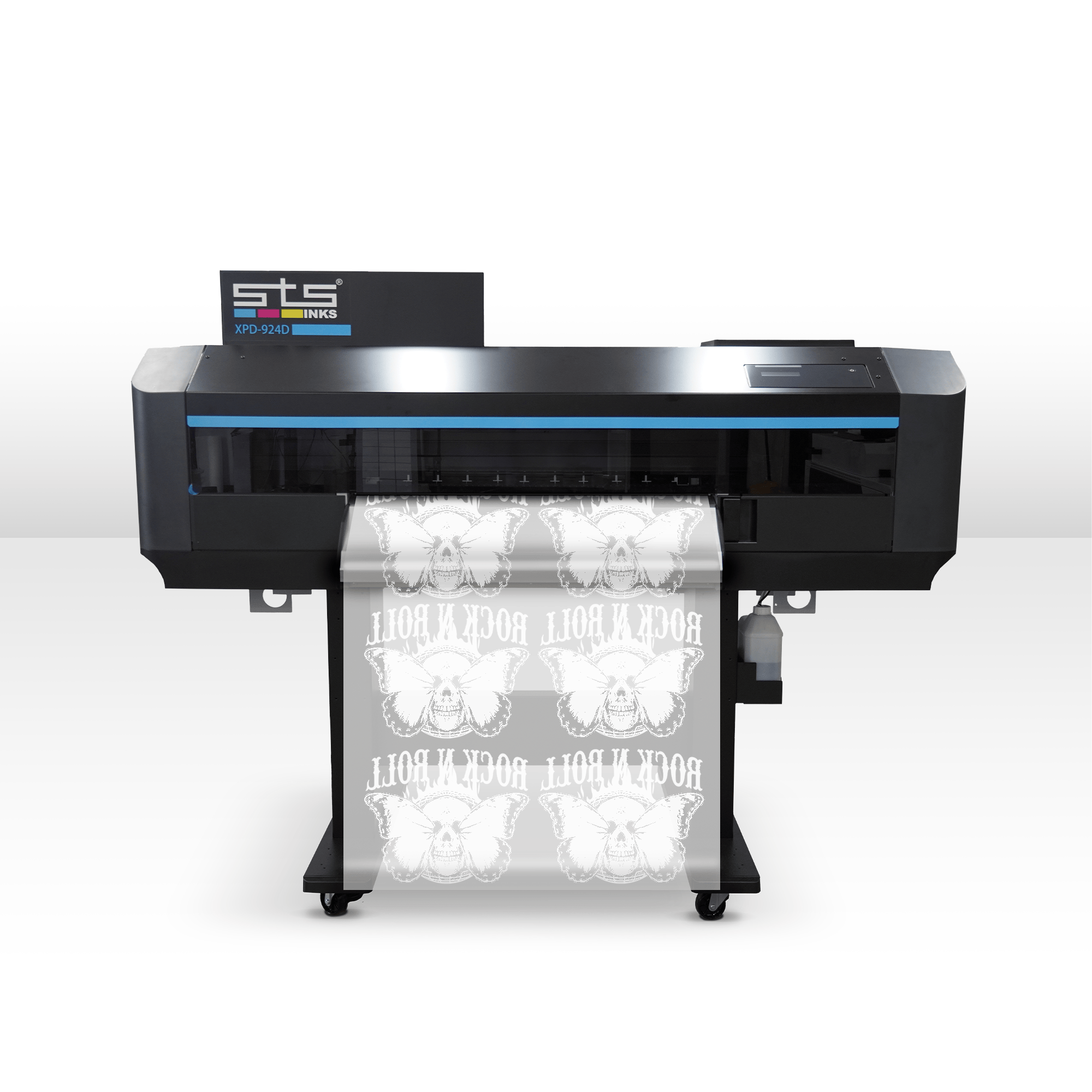

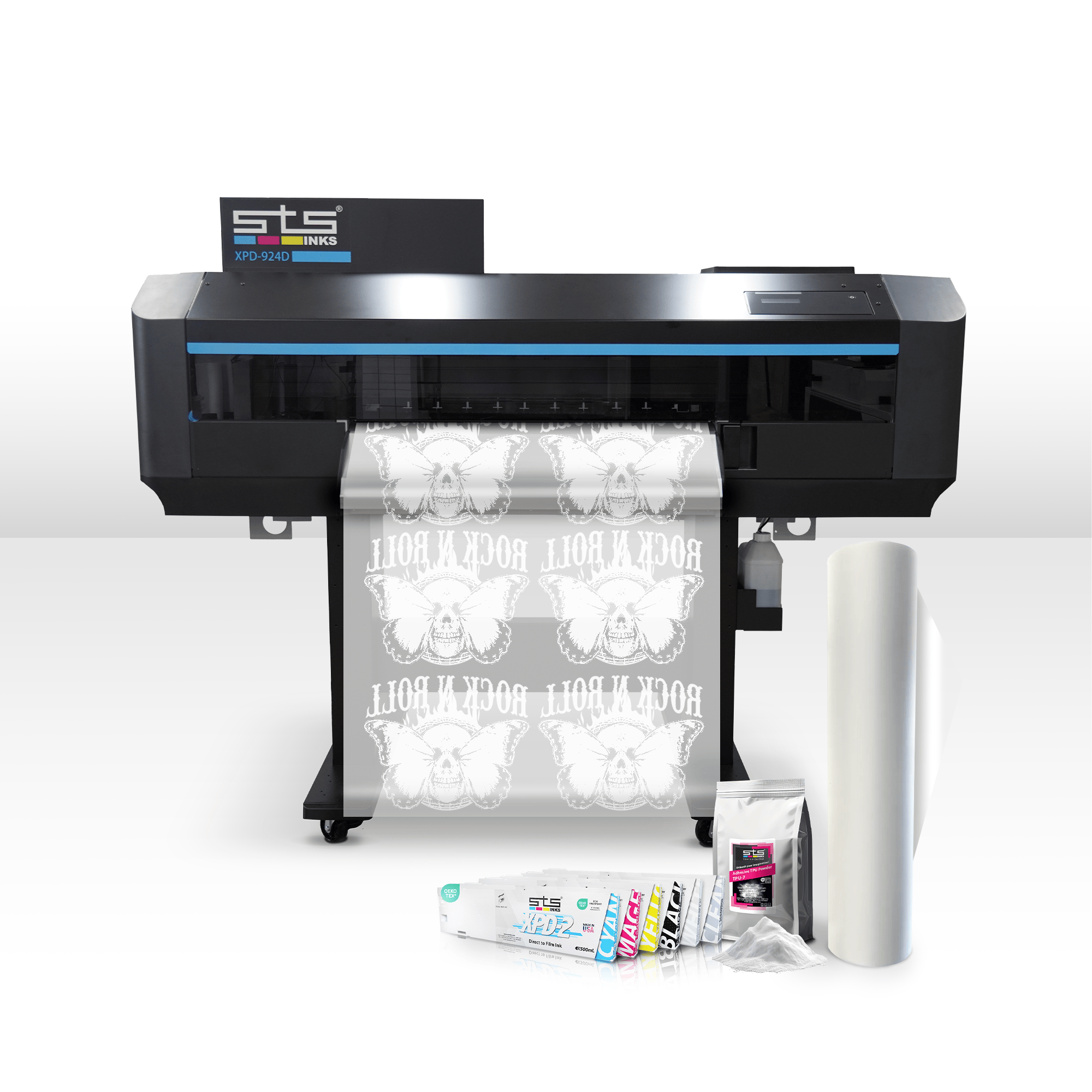

- Complete Turnkey Solutions that Produce Exceptional Transfers that are Super Soft and Colorful with Excellent Elasticity, and Washability which Creates the Industry’s Finest Hand Feel Transfers.

Specifications

| Printing method | Drop-on-demand Micro Piezo Inkjet Technology |

|---|---|

| Print head height | Four-level adjustment: 1.5mm, 2.0mm, 2.5mm, 4.0mm |

| Print head | 2 (staggered) |

| Max print resolution | 1200×1200 dpi (1200/900/600/300 dpi print modes) |

| Media width | 60 cm 25″ |

| Media capacity | ø 5.9” dia / 2” & 3” cores | Roll media 66lbs or less |

| Max media thickness | Low 1 0.3mm, Low2 0.8mm, Mid. 1.3mm, High 2.8mm |

| Max printable width | 24.5 in |

| Max print speed | 17.5 sqm/hr – 188 sqft/hr |

| RIP software | CADlink™ Digital Factory 11 / IneditTM neoStampa |

| Interface | Gigabit-Ethernet (1000BASE-T) |

|---|---|

| Power Requirements | Four-level adjustment: 1.5mm, 2.0mm, 2.5mm, 4.0mm |

| Print head | Temperature: 68-77°F / 20-26° C Humidity: 40-55% |

| Power Consumption | Main: Operation status 70W or less Standby: 30W or less |

| Dimensions (WxDxH) | Printer including stand: 70.68″x35.23″x56.48″ cover closed |

| Weight | Body: 310Ib I Stand: 70.54Ib / Body: 140kg I Stand: 32kg |

| Inks | Type | DTF |

|---|---|---|

| Ink Set | 4 color (CMYK) | White | |

| Volume | 500 ml Direct to Film Inks Cartridge XPD |

|

| No. of slots | 6 |